Various approaches have had reasonable success in reducing unsafe behavior's in the workplace. Some involve penalties; others involve surveillance; others involve guidance, codes and procedures to follow; others still are supportive and training-oriented.

Some initiatives come from the employer, from the social partner organizations, from state regulatory bodies, and some worthwhile initiatives come from individual employees’ own insights, ideas, training and development activities around health and safety.

Most employers and employees in the area of safety will agree that the ultimate aim of a safety

initiative is a “total safety culture”; however, this concept is rarely defined. A total safety culture is a culture in which:

a) Individuals hold safety as a ‘value’ and not just a priority;

b) individuals take responsibility for the safety of their co-workers in addition to themselves; and

c) all level of employee are willing and able to act on their sense of responsibility – they can go ‘ beyond the call of duty’

The following are some requirements for any approach to safety at work that brings about noticeable, lasting results and contributes to a total safety culture:

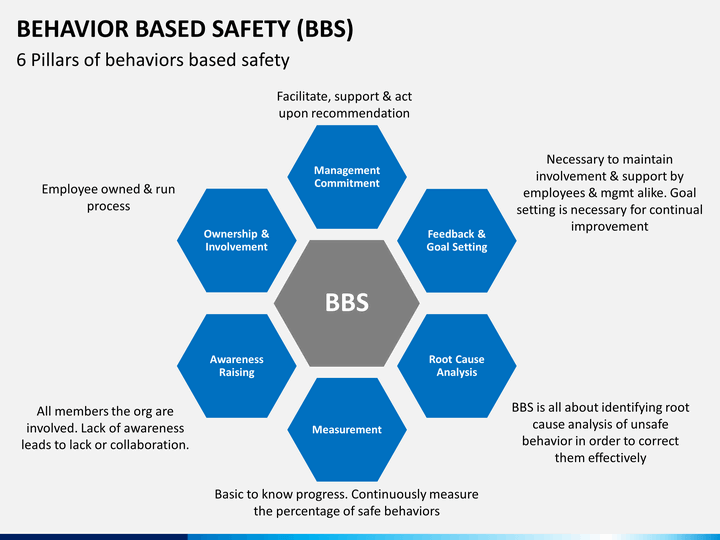

Behavior Based Safety or BBS is a scientific approach to positively reinforce a safe work environment by modulating unsafe behavioral patterns. A BBS system focuses on how people work, analyzes why they work in a certain way and applies an intervention strategy to eliminate unsafe behavior.

The importance of a behavior based safety program lies in its pragmatic approach to remove the most common source of workplace injuries or accidents - "human error".

While human error is non-deliberate, it emancipates from our casual behavioral tendency of being complacent while undertaking high-risk jobs. Front line workers are often prone to human errors as they tend to neglect the finer aspects of safety while following routine operations. As experience manifest in faster results, these workers tend to take risky shortcuts that go undetected. This change in behavior influences a dangerous pattern that ultimately leads to an accident - causing harm to themselves and those around them.

While human error is non-deliberate, it emancipates from our casual behavioral tendency of being complacent while undertaking high-risk jobs. Front line workers are often prone to human errors as they tend to neglect the finer aspects of safety while following routine operations. As experience manifest in faster results, these workers tend to take risky shortcuts that go undetected. This change in behavior influences a dangerous pattern that ultimately leads to an accident - causing harm to themselves and those around them.

With a BBS program, your entire organization from the management to frontline workers is constantly under observation to discover unsafe or destructive behavioral tendencies. A comprehensive BBSO program observes employees while they perform routine tasks, providing them with continuous feedback, motivation and awareness to reinforce their behavior to align with safe work practices.

The primary goal of a BBS program is to positively reinforce safe practices by proactively identifying naturally inclined unsafe behavioral patterns in humans and ensuring that timely interventions are in place to encourage individuals or groups to continuously conform to EHS best practices.

Behavior-based safety is often called the Swiss Army Knife of safety programs for its multi-functional uses. When approached correctly, BBS has a myriad of benefits that make sites safe, productive, and improve morale. These are just a few benefits managers can expect when implementing BBS correctly:

This guide is informed by the field of Behavior- Based Safety (BBS), which is often described as a bottom-up approach (frontline employees), with top-down support from safety leaders. A behavior-based safety approach promotes interventions that are people-focused and often incorporate one-to-one or group observations of employees performing routine work tasks, setting goals carefully and giving timely feedback on safety-related behavior, coaching and mentoring. The initiatives have a proactive focus, encouraging individuals and their work groups to consider the potential for incident involvement, (accidents) and to assess their own behavior as safe or unsafe always, no matter what.

This guide is informed by the field of Behavior- Based Safety (BBS), which is often described as a bottom-up approach (frontline employees), with top-down support from safety leaders. A behavior-based safety approach promotes interventions that are people-focused and often incorporate one-to-one or group observations of employees performing routine work tasks, setting goals carefully and giving timely feedback on safety-related behavior, coaching and mentoring. The initiatives have a proactive focus, encouraging individuals and their work groups to consider the potential for incident involvement, (accidents) and to assess their own behavior as safe or unsafe always, no matter what.

A BBS approach is one which:

BBS stems from the field of organizational behavior analysis. The focus in both organizational behavior analysis and BBS is behavior. The overarching theme in behavior analysis and BBS is that behavior is maintained by what occurs after it (consequences).

Many safety interventions in work settings focus on antecedents, or events that come before behavior that may evoke behavior. For example, many work settings rely heavily on training, safety signs, pep talks, toolbox talks, or pre-briefs. These can be effective in activating behaviors initially, but it is what occurs after our behavior that ensures the behavior will occur time and time again.

Within BBS, behavior is explained in terms of the ABC model (Antecedent, Behavior, Consequence).

The ABC model or the Antecedent-Behavior-Consequence model is the well-established and scientific approach to analyze why people act in a certain way and find ways to implement behavioral changes.

According to this cognitive behavior therapy, The A stands for antecedent, which is the prevailing condition that works as a catalyst for the preceding action. Antecedents reveal what set off the behavior.

The B stands for Behavior, which is defined as the visible action that a person performs which is observable and measurable.

The C stands for consequence; it is the action that takes place after the outcome of the behavior is triggered. It could either be positive or negative depending on the result of the behavior.

Rectifying antecedents may be a safe bet for controlling risky behavior. However, it is the consequence of a behavior that can effectively reinforce behavioral changes

When we examine an incident report and ask questions around why a person behaved in a certain

way, we tend to look at antecedents, or what occurred to ‘set off’ the behavior. However, if we

examine the report with a view to consequences, we will gain a clearer picture of why the behavior

occurred. For example, if an eye injury occurred and the individual was not wearing PPE, we need to examine what were the consequences for wearing the PPE (e.g., possible but not definite reduction of injury) and what were the consequences for not wearing PPE (e.g., immediate comfort, better vision

on the job).

A behavior-based checklist is generally used for directly observing on-field behavioral patterns. The checklist serves as a powerful tool to identify unsafe acts, identify root causes and list down corrective measures. Commonly used behavior based checklist usually includes:

Here is a 7-step process that can help in improving Behavior Based Safety in your organization:

1. Identify critical problem behaviors.

2. Identify root causes.

3. Generate potential actions.

4. Evaluate possible actions.

5. Develop an action plan.

6. Implement an action plan

7. Conduct follow up.

To implement a strong behavior based safety program, your organization should inculcate a safety culture that promotes:

Open Communication:

Create a feedback-rich environment where employees can freely voice their concerns and where the management conducts consistent awareness programs.

Reporting Culture:

Promoting a culture where are all dangerous activities/behaviors are duly reported to take timely actions.

Management commitment:

Ensure company-wide transparency in following safety procedures from owners, safety officers, and other high ranking officials.

Timely Reaction:

Be quick to act on unsafe behavioral reports, align teams to rapidly spread precautionary measures before it escalates into an incident.

Create a checklist from target behavior:

Utilize data from safety audits, safety meetings to find site vulnerabilities and identify critical safe behaviors that can be implemented in the observational checklist.

Employ a measurement system:

Ensure that there is a mechanism that weighs the frequency of safe and unsafe behaviors during an observation

Carry out observations

Conduct regular observation with trained HSE professionals who can blend into the work environment without acting as a deterrent to work procedures.

Deliver Consistent Feedback

Make sure that dangerous behavior that is observed is conveyed to the employee as fast as possible - creating an immediate feedback loop where the employee voices his concerns and overall corrective action is determined by the management.

Utilize data to take corrective action:

With valuable observation results at hand, find trends that need immediate corrective measures, ensure that all staff is informed of any newly discovered anomaly or prevalent condition.

Evaluate change:

Set improvement goals by monitoring the effectiveness of each behavioral modification, implemented as a countermeasure to obtain positive results.

The effectiveness of a properly implemented BBSO system is undeniable in curbing unsafe acts, yet negative safety trends such as negative reporting quotas and wrongful implementation of the BBS program can prove disastrous to your organization. Here are a few common challenges and mistakes to avoid while implementing a BBS program:

Pushing the buck onto employees:

While the unsafe risk taker may be the blip in your safety program. Creating an environment where the blame game leads to unwarranted frictions can prove a dangerous mindset for your organization. A BBS system requires active employee participation through positive reinforcement and motivation to effectively sustain and bear results.

Failure to apply positive reinforcement:

It is natural for people to elicit a certain behavior, be it safe or unsafe acts, if it provides some form of benefit. In the workplace, taking a risk may save time, effort and in some cases ease into our comfort zone. With no leading indicators to affect change, the behavioral pattern will continue to manifest. Behavioral change should stem from positive reinforcement and safety culture that imbibes open communication and facts. Employees need to know the specifics of the hazards they are likely to face due to their behavior and the management also must provide an alternative solution to contain the hazard.

Failure to engage participation:

Resentment at being constantly admonished for unsafe practices may sway employees away from participating or even reporting unsafe acts due to fear of being reprimanded and terminated. To imbue a culture of active participation, companies need to make their staff feel like valued contributors to your safety culture and take to rewarding safe acts rather than punishing bad behavior. Unsafe behavior must be delicately conveyed using a corrective action process.

Reinforcement occurs when a consequence that follows a behavior makes it more likely that the

behavior will occur again in the future. Therefore, a reinforcing consequence is one that causes behavior to occur more frequently.

For example, the behavior of putting money in a snack vending machine and pressing a button has the consequence of the chosen food item being distributed. The presentation of the food item putting the money in and pressing the button. If the person using the vending machine actually

wanted the food item then they will repeat this behavior in the future (because it was successfully accomplished).

We can increase performance through negative and positive reinforcement.

A lot of what we do is to avoid something, so we behave to get rid of the thing we don’t want

– this is negative reinforcement.

For example, if you wear PPE to avoid a fine (that might occur for not wearing PPE), this is you working under negative reinforcement. Your ‘wearing PPE’ behavior has increased in order to avoid a bad situation.

Doing something to avoid punishment or aversive conditions will not inspire great or creative performance. We get by, but we are not motivated to improve – we are motivated by fear! Working because we ‘have to’ will get sufficient performance, but working because we ‘want to’ will mean we get maximum performance

In many organizations, work is typically carried out under negative reinforcement conditions (i.e.

because we ‘have to’). This results in adequate performance; employees do enough to satisfy a

compliance standard, but they do not go that extra mile. On the other hand, working under positive

reinforcement conditions can result in employees going above and beyond their job duties, and

employees will take personal account for safety. If employees work under positive reinforcement

conditions (i.e. because they ‘want to’), then they will be:

1) working towards something good (as opposed to avoiding a negative),

2) motivated to work, which might result in

3) creative thinking, employing new strategies, successful decision making, seeking more responsibility.

In work settings it is less common to see individuals working under positive reinforcement conditions; however, it is preferable. Positive reinforcement leads to durable behavior change, and happier employees!

For example, if you wear PPE because you feel like you are contributing to safety in your

organization (by taking personal control of safety), you will be more likely to wear PPE when your boss is not present, in situations in which it is not mandatory, and you may well begin to exhibit other safe behaviors in addition to this, voluntarily.

Doing something that results in positive reinforcement promotes strong, durable behavior change, in addition to other new positive behaviors.

When we talk about reinforcement, we refer to the consequence that increases behavior as a

reinforcer.

A reinforcer is anything that is added following a behavior that increases that behavior in the

future.

Feedback is information given to an individual or a group about their behavior and its impact

(Braksick,2007), and is one of the most important communication tools in helping people stay

healthy and safe. Feedback can take many shapes and forms, and generally in a work setting feedback is a combination of positive and constructive information.

A feedback-rich environment enhances both communication and motivation. Positive feedback can act as a consequence that increases behavior (reinforcement). Feedback lets us know that we are

A feedback-rich environment enhances both communication and motivation. Positive feedback can act as a consequence that increases behavior (reinforcement). Feedback lets us know that we are

performing the correct behaviors – positive feedback should be specific in pinpointing the exact

behaviors that warrant positive praise. For example, instead of saying “nice work Bill”, saying “Bill, your housekeeping skills are so impressive. My path is always clear walking through your

workspace”, will convey exactly to Bill what he has done to impress the person delivering the feedback. If individuals receive feedback telling them that they are doing ‘the right thing’, then they will most likely increase that behavior, provided the feedback is specific and genuine.

Sometimes it is necessary to deliver constructive feedback. Constructive feedback refers to when

clear non judgmental instructions are given to the individual on what behaviors they need to change to reach the desired behaviors’. If positive feedback is delivered on a ratio of 5:1 to

constructive feedback, then it will be easier for the communicator to deliver the constructive feedback, and for the listener to receive the feedback. If a person is habituated to receiving positive feedback, when he/she receives constructive feedback indicating that a change in behavior is required, the person will make the changes, particularly if a goal is set around the new behavior.

We often ‘do’ incorrect things because we haven’t been shown how to do the correct things.

Using feedback in conjunction with goal setting provides a clear objective for the individual, so a

combination of goal setting and frequent feedback produces maximal behavior change.

Research into motivation and behavior change tells us that setting goals leads to better results and that ‘what gets measured gets done’. A person who is encouraged to get sixty letters typed in a day is far more likely to succeed than a person who is told to ‘do their best’. Likewise, if there is any room for ambiguous interpretation, it is crucial to elaborate, e.g., rather than saying ‘Overalls should be worn correctly’, say, ‘Overalls should be done up to the neck with sleeves outside gauntlet gloves’. It is better to be specific than vague, to aim higher than lower and to get participation and engagement from the start. Safety should always be at the core of goal setting: saying ‘Do it by Friday but do it safely’ rather than ‘Do it safely but do it by Friday’ puts the emphasis on safety as the most important factor, not the deadline.

Research into motivation and behavior change tells us that setting goals leads to better results and that ‘what gets measured gets done’. A person who is encouraged to get sixty letters typed in a day is far more likely to succeed than a person who is told to ‘do their best’. Likewise, if there is any room for ambiguous interpretation, it is crucial to elaborate, e.g., rather than saying ‘Overalls should be worn correctly’, say, ‘Overalls should be done up to the neck with sleeves outside gauntlet gloves’. It is better to be specific than vague, to aim higher than lower and to get participation and engagement from the start. Safety should always be at the core of goal setting: saying ‘Do it by Friday but do it safely’ rather than ‘Do it safely but do it by Friday’ puts the emphasis on safety as the most important factor, not the deadline.

Goal setting means simply what it says:

1. A design team is created The most effective way to run a BBS programme is to initially set up a design team. The design team should consist of management and frontline employees, and each member of the team should have heard about BBS and volunteer to be on the team. This team will design the BBS system, however all employees will be involved in implementation.

2. Target behaviors are chosen from safety incidents, near miss reporting, safety audits and observation Firstly, the design team picks targeted areas/ tasks. The team can use data that the site already has; results of safety audits, safety data, information from safety meetings and informal interviews with staff (from the past 5 years if possible). This will provide a wealth of

information around areas in need of improvement. The team determine what would have prevented the reported injuries; if it is not immediately obvious the team use methods like discussing how increased situation awareness might have affected the situation. From this analysis, the team will identify critical safe behaviors for an observation checklist.

3. A critical checklist is developed The checklist is comprised of the list of safe behavior's identified in the above step. The list can be shortened according to importance of safety, frequency of occurrence, observability and overlap with other items on the list. The list should be no more than 1 sheet of paper (1 side). It helps to have definitions for everything that is being measured on the back of the checklist – try not to leave anything up to subjective interpretation. The best way to know if the checklist is useable is to observe an employee working, and see if all categories on the list can be filled out in an observation. The list will need to be revised a number of times before it

can be considered ready-to-use.

4. Ensure that you have a measurement system The measurement system for an observation

programme is simply a frequency count of safe and risk behaviors during an observation. Note of caution: measuring is an antecedent, and we need a consequence in place to strengthen the

behavior under measurement. When measurement is used effectively, the leader can create an environment in which people actually want to be measured. This can happen when positive consequences are delivered based on the behavior change that is observed through measurement. When employees receive specific, positive feedback about the results, then they will see a benefit,

aim higher, and want to be measured.

5. Behavioral observations are carried out Consider who will conduct the observations. Data shows that the most beneficial system is to have all employees involved in the observation process. Behavioral observations increase safety behaviors of the observed but also the observer, so encouraging employees to conduct observations on each other will benefit all employees. The team and all employees will need to decide how often observations will be conducted. Will they occur across or within departments? Will a single task or employee be observed, or a work area? Will you include contractors? – if so, try to recruit them at the design phase.

6. Feedback is delivered The process requires careful training of employees. The observer should summaries significant positive safety behaviors that were observed and then one or two areas that require change. The feedback should be delivered as soon as possible after the observation (unless this poses a risk). Describe the behavior observed, discuss the potential impact and listen to the observe – this formula can be used for both positive and corrective feedback. In addition to individual feedback by the observer, overall site feedback should be delivered. The leader should discuss the results of the observations (categorically, not personally) at safety meetings, while also providing visual feedback. The easiest and most effective way to do this is through creation of a graph. Visual feedback helps us to see how we are doing and also helps us to set goals. Leaders should respond with positive feedback about any improvements, and not respond negatively to low numbers on graphs. Instead, they should encourage objective problem solving.

7. Make use of the data You now have valuable data that you can use of inform you on process changes. Build a review of the data into existing meetings and ensure that all staff are informed of any changes made based on the data, and that they know it was because of their contribution

(as a group - no names are recorded).

8. Set improvement goals Employees should be encouraged to participate in this, and the goals should be realistic and based on the current data. Set short goals and ensure that each employee

knows what behavior or process they need to work on to reach the goal (see goal setting section of this guide). Remember to focus on the safety process itself and not the results – attempting to manage results will ruin the integrity of the programme. Instead of setting goals to increase or decrease results, set goals around the behaviors that lead to these results (e.g., increase wearing of safety goggles from 80% to 100%).

Behavioral observations are an opportunity to deliver both positive and constructive feedback. It is

a feedback session structured around observation of a particular behavior or a set of behavior's, and a feedback-rich environment is one in which everybody is learning. An effective observation

process offers:

There are numerous benefits of using a behavioral observation approach, and it is recommended that the reader consult the reference section of this guide for examples of successful interventions.

Some notable benefits of behavioral observations are:

Click the below links to know download BBS observation safety check sheet, PPT-1 & 2, 32 toolbox talks

Behavior based safety - Power point presentaion-1

Behavior based safety - Power point presentaion-2

Behavior based safety - Observation safety check sheet

Behavior based safety - 17 Safety toolbox talk-Part-1

Behavior based safety 15 Safety toolbox talk-Part-2